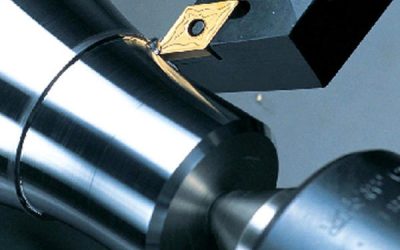

CNC Machining

The Vo-Tech team is your team, driven to provide you with exceptional quality, close tolerance, and precision-machined parts. Experienced and trained machinists with a background of serving a wide array of industries, provides a unique skill set to tackle just about any job. Our team of engineers can also review designs and propose optimizations that will increase your accuracy, efficiency and costs across the board.

Our customer says:

“Recently our workload has gone through the roof. We gave Vo-Tech more difficult jobs and this significantly freed up our machine time for other critical jobs. The team at Vo-Tech delivered with outstanding quality, worked well with our team, and applied our requirements and suggestions. We value our partnership with Vo-Tech, they are a family-owned business that sees the big picture, makes quality products on-time, and their friendliness and open communication is unparalleled.”

– Production Manager at Large Plastic Parts Manufacturer

CAPABILITIES

| CNC Milling |

|---|

| Laser |

|---|

| CNC Turning |

|---|

| Rapid Prototyping |

|---|

| Wire EDM |

|---|

| Short-Run Production |

|---|

FEATURED MATERIALS

- Aluminum

- Brass

- Copper

- Steel

- Stainless Steel

- Titanium

- ABS

- Acrylic

- Nylon

- Polycarbonate

- Teflon

- Delrin

- HDPE

- Thermoform Models

- REN Board

Need a Finishing Service?

Whether you need

anodizing

nickel

chrome

black oxide

heat-treating

grinding

passivation

and others, you can be assured we have long-term partners in these areas that we work with on a continuous basis.

EQUIPMENT DETAILS

Whether it’s a single component or a high-volume production, our facility specializes in close tolerance work. Prototypes and development parts are made to print specifications.

For a full list of equipment, visit this page

CNC Vertical Mills

- Vacuum chucking systems for hard to hold and ultra thin part machining

- Full 4th axis capability with 1.75” spindle through hole and up to 8” chucking diameter

- High speed spindle up to 12,000 RPM’s

- High pressure programmable coolant nozzles

- High pressure coolant through tooling capable

- Vast inventory of unique fixturing to increase efficiency or we can build necessary fixturing

CNC Lathes

- Chucking up to 40″ diameters and 80″ lengths

- Live tooling equipped for cross and 4 axis work

- 2.5” spindle diameter/throughput

- Coolant through tooling capable

- Live tooling for 4 axis work

- Sub spindles for efficient back end work

- 23” of swing and 17” of OD chucking

Wire EDM

- 5 axis CNC wire EDM with max part size of 24″ x 16″ x 12″

Laser

- 120 Watts of cutting/engraving power.

- Work envelope of 39″x24″x12″ with pass-through for unlimited Y length.

- Capable of cutting an array of plastics and engraving plastic and metal.

Manual Lathes

- Shaft work up to 6 feet in length

- 4.5″ spindle bore, 22″ swing, and 100″ between centers.

OTHER EQUIPMENT

- Cosen automatic production cut off saw

- Cosen automatic production cut off saw

- Tekna precision extrusion cut off saw

- Manual engine lathes with DRO’s

- Bridgeport manual mill with DRO

- Surface grinders

- Welder

- Blast cabinets

- Forklifts, bridge crane, etc.

- 100 Ton Hydraulic Press

- Miscellaneous sanders, grinders, etc.

For a full list of equipment, visit this page