Do you need a reliable vendor that understands the Nuclear culture, the urgency of getting things done safely, the right way, the first time? If the answer is yes, you are in good hands. Vo-Tech’s skilled team has served the needs of the power generation industry for over 20 years. Our experience has given us tremendous insight into solving problems and saving money for our customers. We efficiently find the best solutions – extremely valuable during the critical path activities, when your time is of essence.

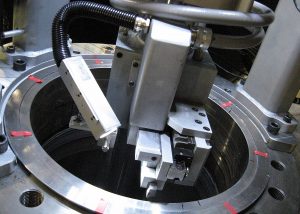

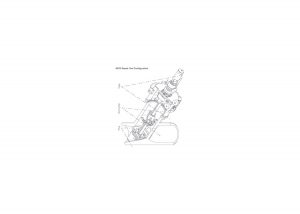

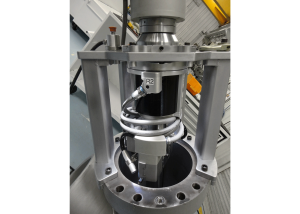

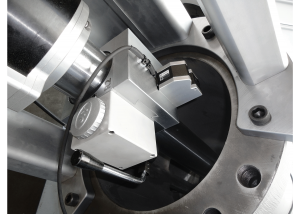

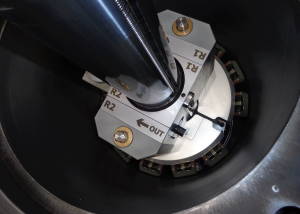

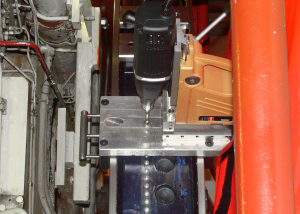

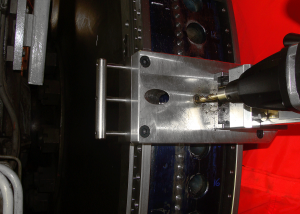

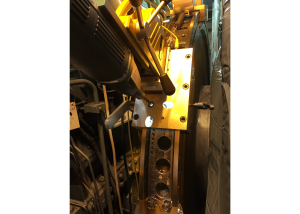

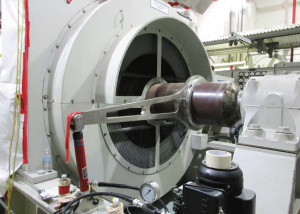

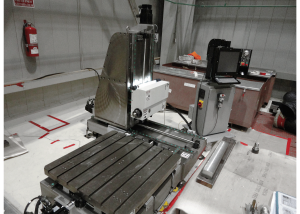

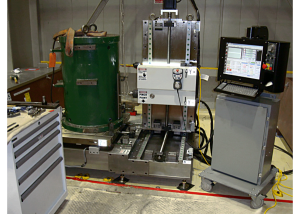

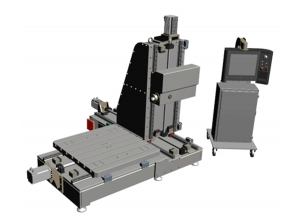

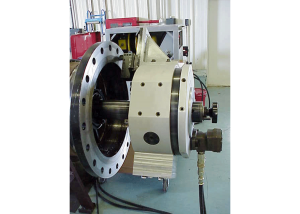

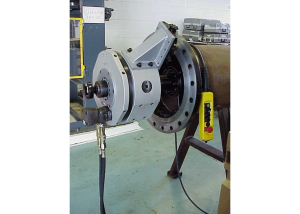

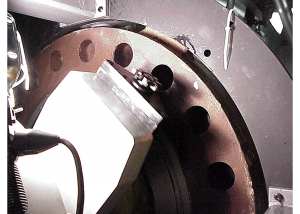

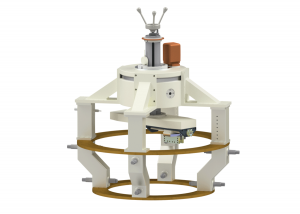

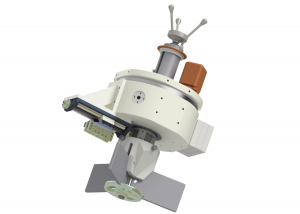

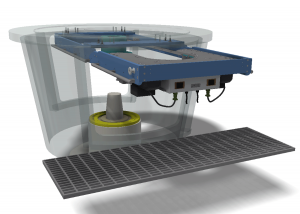

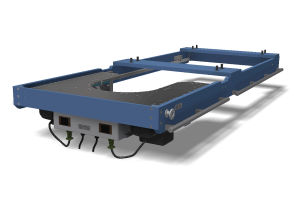

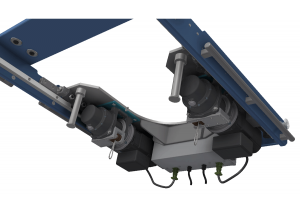

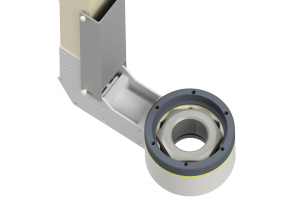

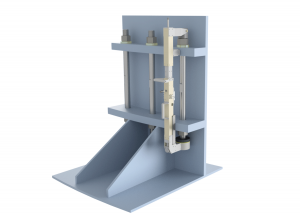

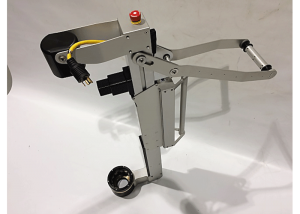

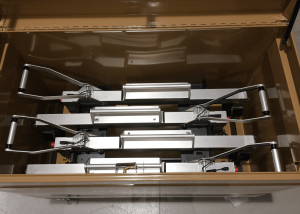

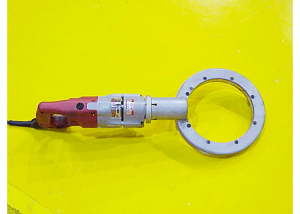

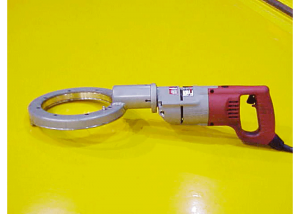

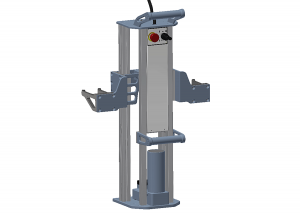

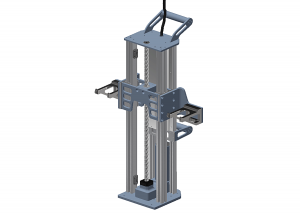

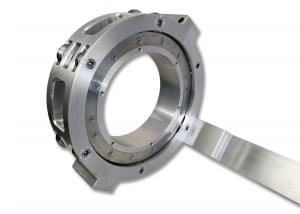

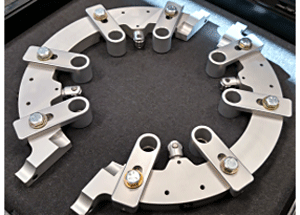

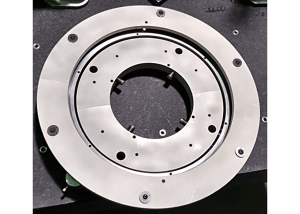

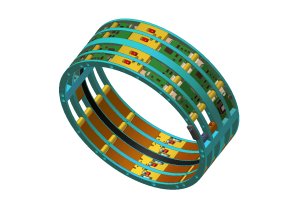

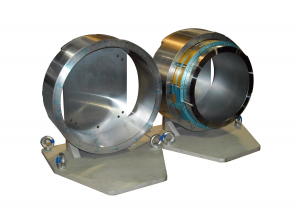

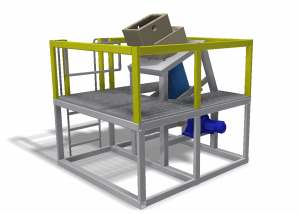

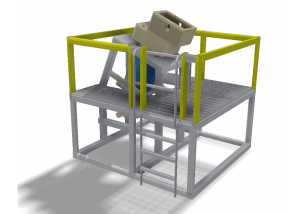

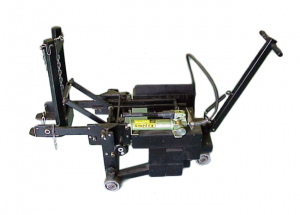

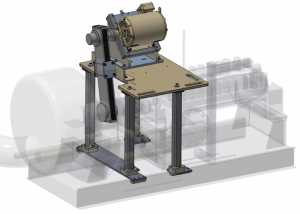

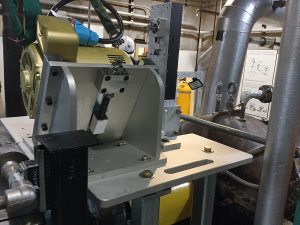

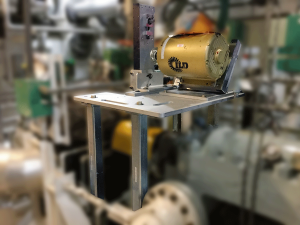

Ask us about our MSIV Modification System, EDG FlyWheel Modification, and Shop Upgrades!